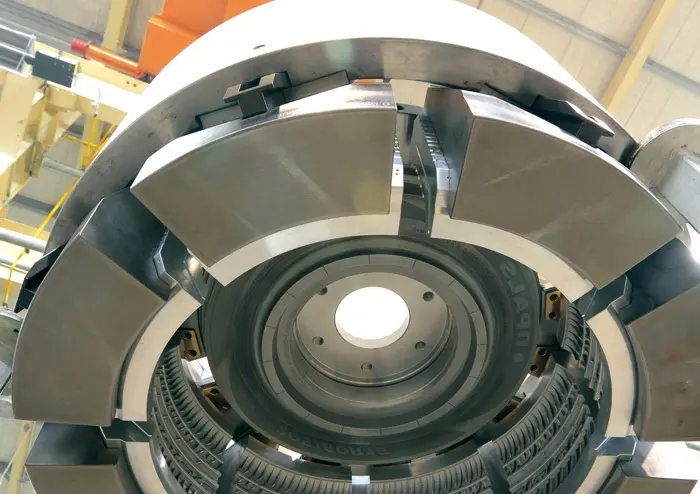

Cavity: The mold cavity that constitutes the contour of the tyre mold product

Centripetal mechanism: a group of parts that form the mold shell and drive the opening and closing of the pattern blocks

Blocks: Model parts for tire tread pattern vulcanization

Sidewalls: Model parts vulcanized on the side of the tire and its logotype

Steel rim: model parts of the tire rim that are shaped and vulcanized

Parting surface: the contact surface between the pattern block and the pattern block, the contact surface between the pattern block and the sidewall plate

Slider: a mold part used to carry the pattern block and transmit the power from the middle mold sleeve during the mold opening and closing process

Middle die sleeve: The combination of parts that transmits power from the vulcanizer and drives the die

Anti-friction plate: a special material part that reduces the friction of each sliding part of the mold

Steam chamber: a cavity structure set in the middle mold sleeve and the upper and lower hot plates by passing steam and heating the mold

Conical surface structure: a structure guided by the inner conical surface and generating sufficient clamping force to drive the mold cavity to close and open

Inclined plane structure: a structure guided by the inner inclined plane and generating sufficient clamping force to drive the mold to close and open

Segmented tyre mold: The radial opening and closing of each block is driven by the centripetal mechanism, which is an integral part of the cavity and the centripetal mechanism.