Cast or forge blanks according to the tire mold drawing. Material: 35#

rough car blank

Machining blanks according to rough turning drawings

heat treatment

The workpiece is fully annealed. To eliminate internal stress, it should be squared during annealing to avoid excessive deformation.

drilling

Drill holes for hoisting according to the drawing.

Semi-finished car

According to the semi-finishing drawing, the outer diameter and height of the full pattern are processed in place, and the inner cavity of the pattern ring is machined with the semi-finishing procedure, leaving 1mm allowance on one side of the sub-port, and the semi-finishing model is used for inspection after turning.

Milling

Use the milling program to rough mill the pattern in the pattern ring (determine whether to mill the pattern according to the tire pattern), leave a margin of 1mm on the half side, and use the milling pattern to check.

EDM

Use the processed pattern electrode to electrically process the pattern in the pattern ring, and use the cavity template and the pattern section template to test.

Scribing, punching, tapping

Divide the pattern ring into several parts according to the requirements of the manufacturer, draw the marked lines respectively, put them in the tooling, punch the back waist hole and tap (that is, the connection hole with the slider).

wire cutting

According to the equal parts divided in step 8, align the scribe line and cut. Use Φ0.18mm wire to cut to 5mm away from the opposite side and exit the incision, the width is not more than 0.20mm.

fitter

According to the requirements of the drawings, the cut pattern blocks should be polished, corners, roots cleaned, vented holes, and vented grooves at the root of the pattern. Traces, conform to the model, after the renovation, polish the exterior of the pattern block as a whole, wash it and wait for inspection.

test

Use the cavity template and pattern end face template to detect the curves and ribs of the corresponding part of the mold. The error should be within plus or minus 0.1mm, the surface finish should be above Ra3.2, and the air grooves and pores should be unobstructed.

sandblasting

The interior of the cavity is evenly sandblasted and the color is consistent.

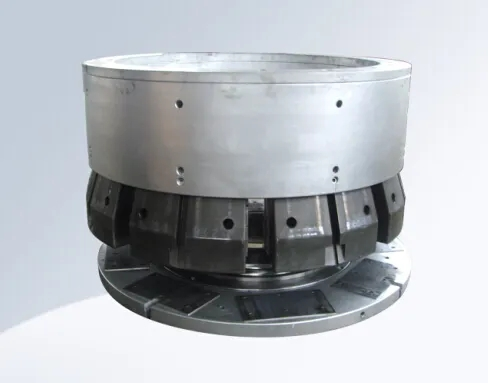

assembly

After grinding and matching the pattern blocks in the tooling, make the car mouth according to the size of the drawing.

Our factory produces all kinds of tire molds,if you need tire molds,welcome to our factory,we will provide the best price and quality tire molds.