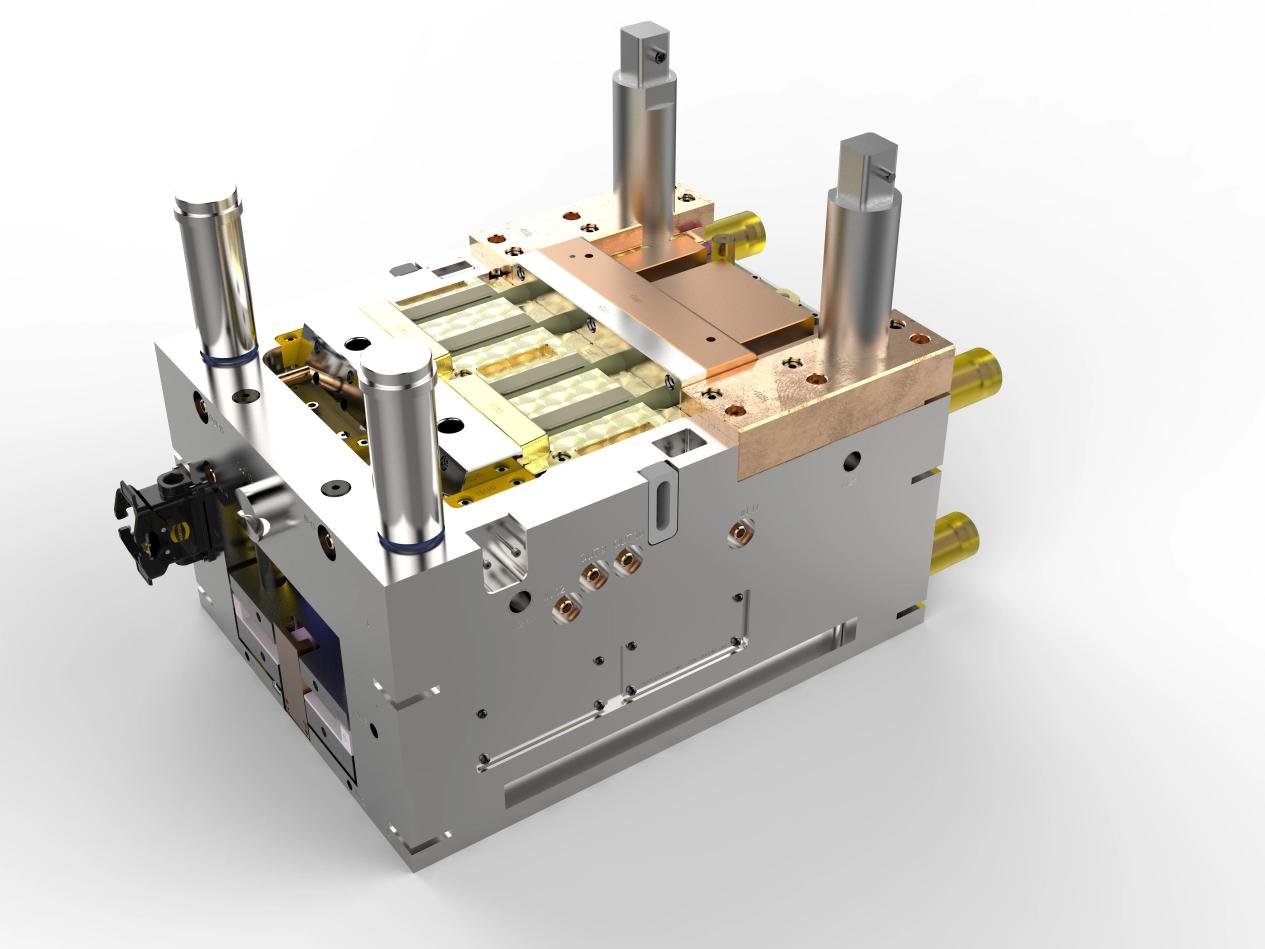

When the single parting surface injection mold is opened, the movable mold and the fixed mold are separated to take out the plastic parts, which is called a single parting surface mold, also known as a double-plate mold. It is the simplest and most basic form of injection mold. It can be designed as a single-cavity injection mold or a multi-cavity injection mold according to needs. It is the most widely used injection mold.

Double parting surface injection mold The double parting surface injection mold has two parting surfaces. Compared with the single parting surface injection mold, the double parting surface injection mold adds a partially movable intermediate plate (and It is called movable gate plate, which is provided with gates, runners and other parts and components required for fixed mold), so it is also called three-plate (moving platen, intermediate plate, fixed platen) injection mold, which is often used for point pouring For single-cavity or multi-cavity injection molds with inlet feeding, when the mold is opened, the intermediate plate is separated from the fixed template by a certain distance on the guide column of the fixed mold, so that the pouring system condensate can be taken out between the two templates. The double-parting surface injection mold has a complex structure, high manufacturing cost, and difficult parts processing. It is generally not used for the molding of large or extra-large plastic products.