Under normal circumstances, the vent hole can be set either at the end of the flow of the melt in the cavity, or at the parting surface of the mold. The latter is a shallow groove with a depth of 0.03-0.2mm and a width of 1.5-6mm on one side of the die. During injection, there will not be a lot of molten material oozing out of the vent hole, because the molten material will cool and solidify there and block the channel. The opening position of the exhaust port should not face the operator to prevent accidental ejection of molten material and injury. In addition, the matching gap between the ejector rod and the ejector hole, the matching gap between the ejector block and the stripper plate and the core can also be used to exhaust air.

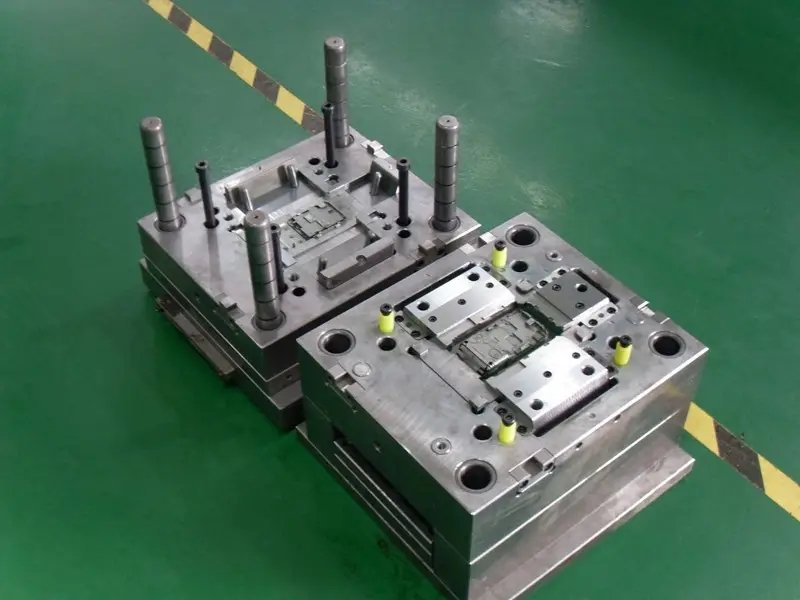

Our factory produces all kinds of injection molds,if you need injection molds,welcome to our factory,we will provide the best price and quality injection molds.